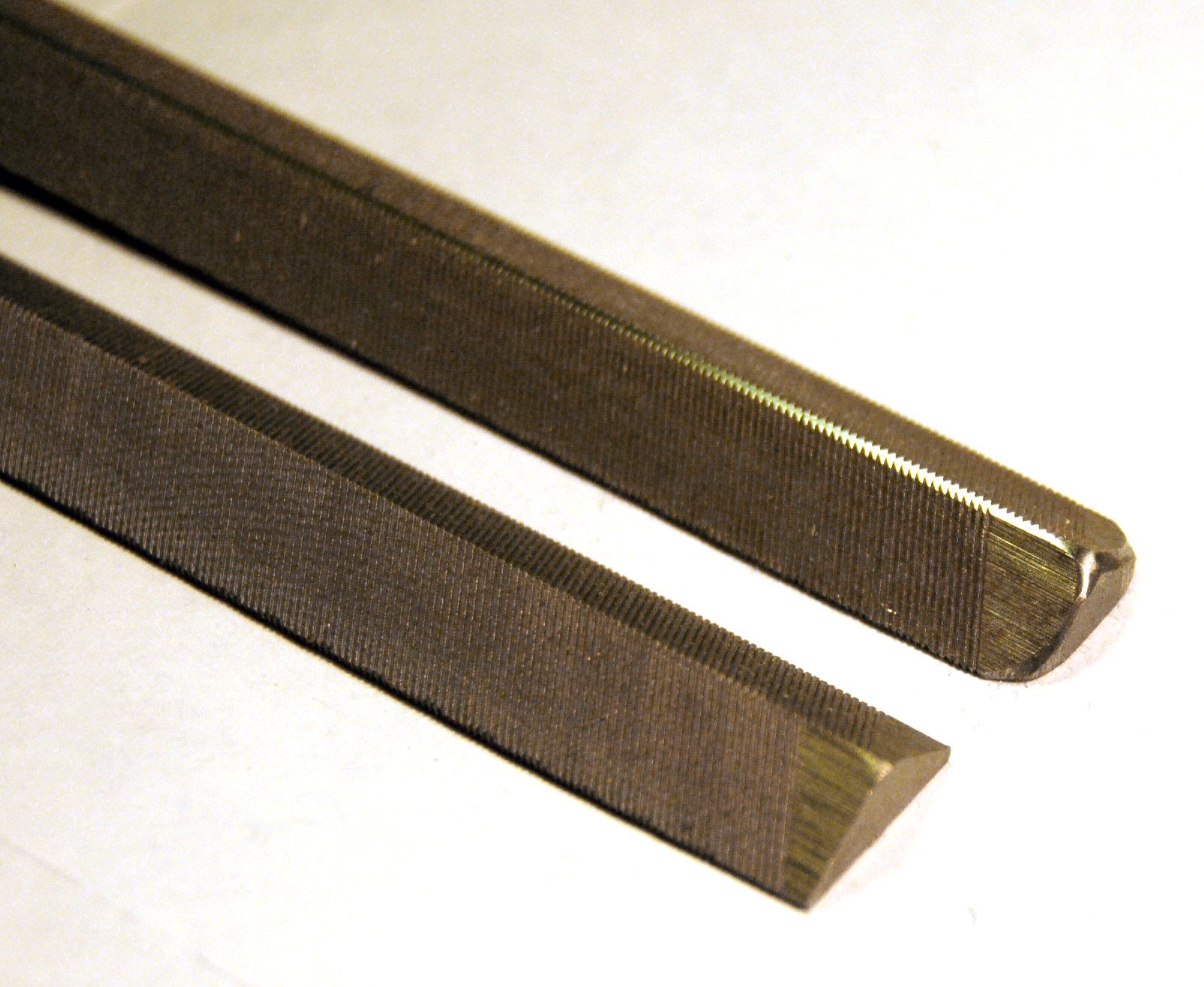

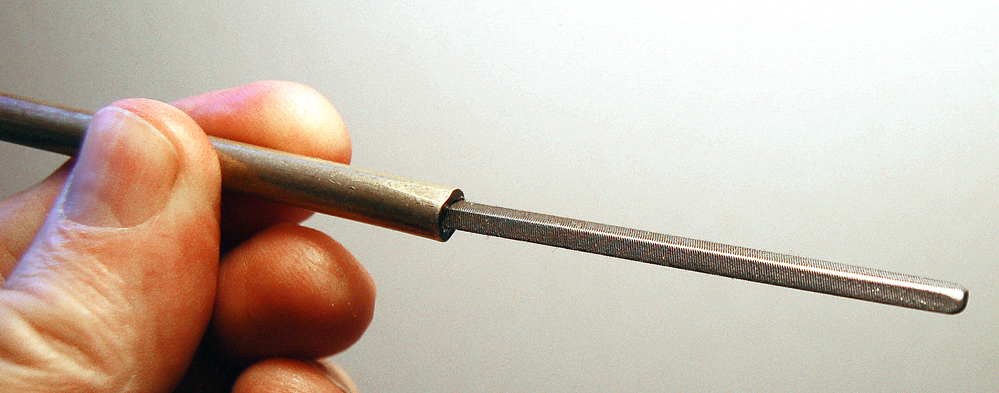

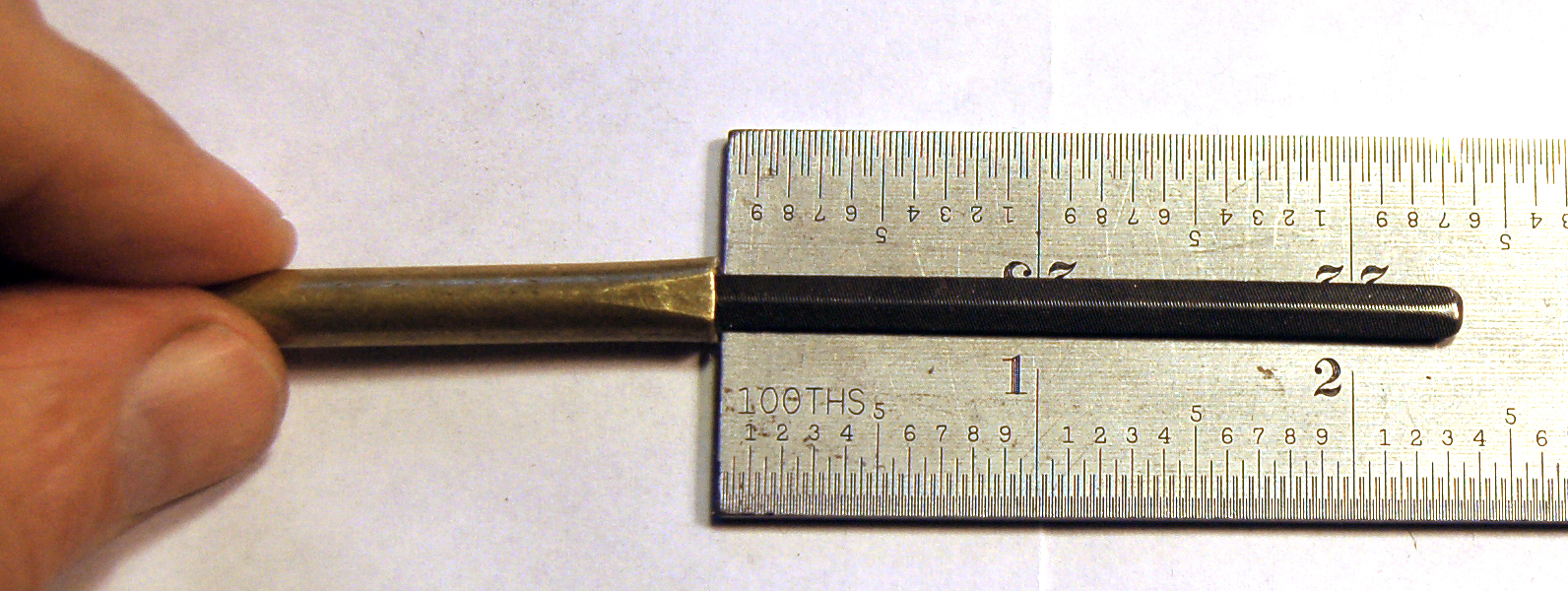

| There are

many files on the modern lutherie market

for cutting slots in nuts and bridges, but most only

became available years after I was doing this work. My

background is in goldsmithing, and I simply adapted the

tools and techniques I learned as a jeweler to work on

musical instruments. Having had the opportunity to try

the commercial fine file sets for luthiers, I haven't

found any of them an improvement over what I use.

Perhaps if I was in a production situation—doing the

same setup over and over, day in and day out—things

might be different. Perhaps if I hadn't evolved my own

methods with the tools that were available to me back in

1960's, I'd make use of them. In any case, I can do any

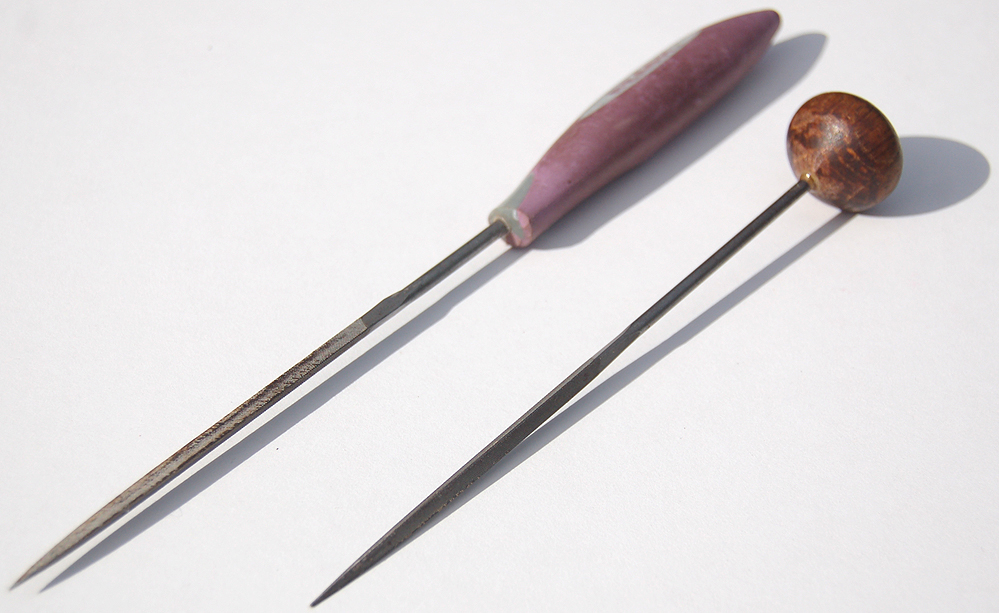

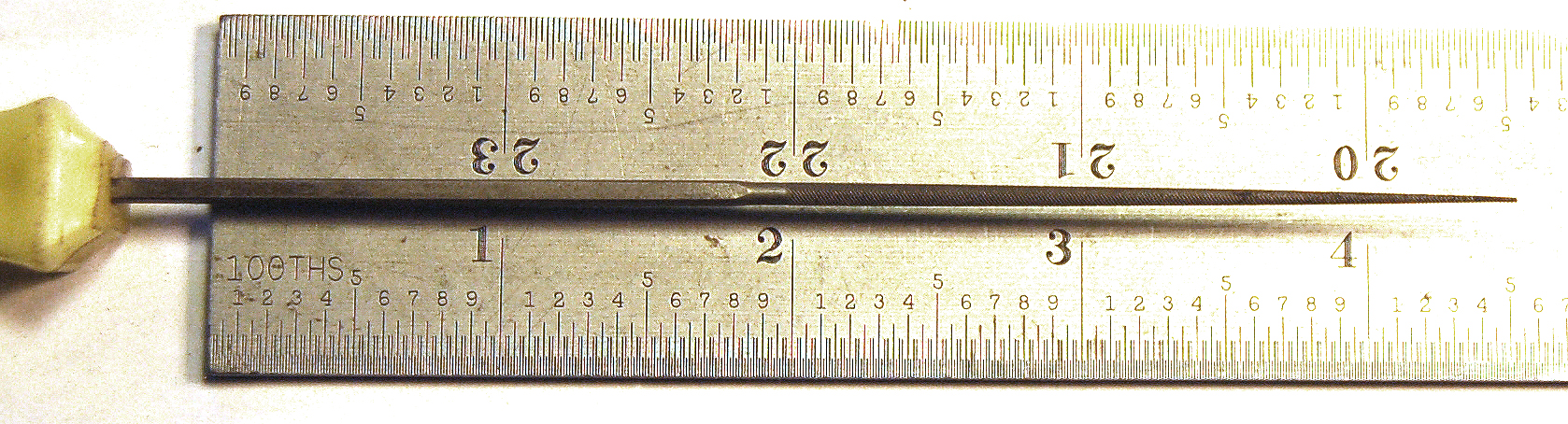

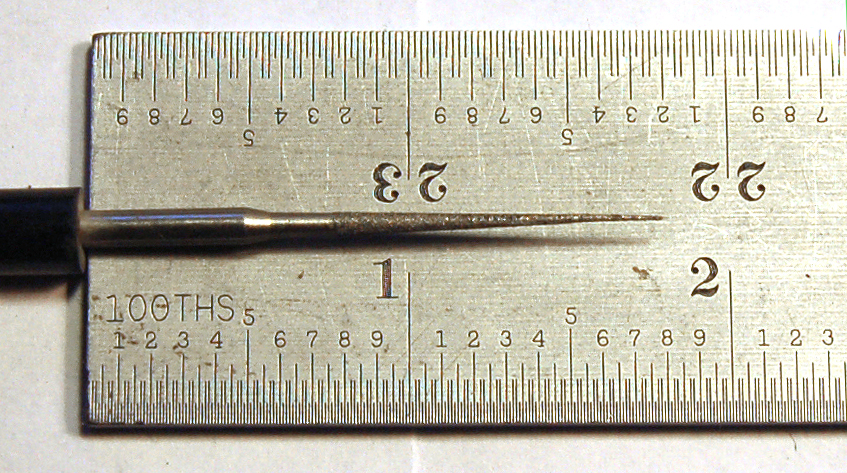

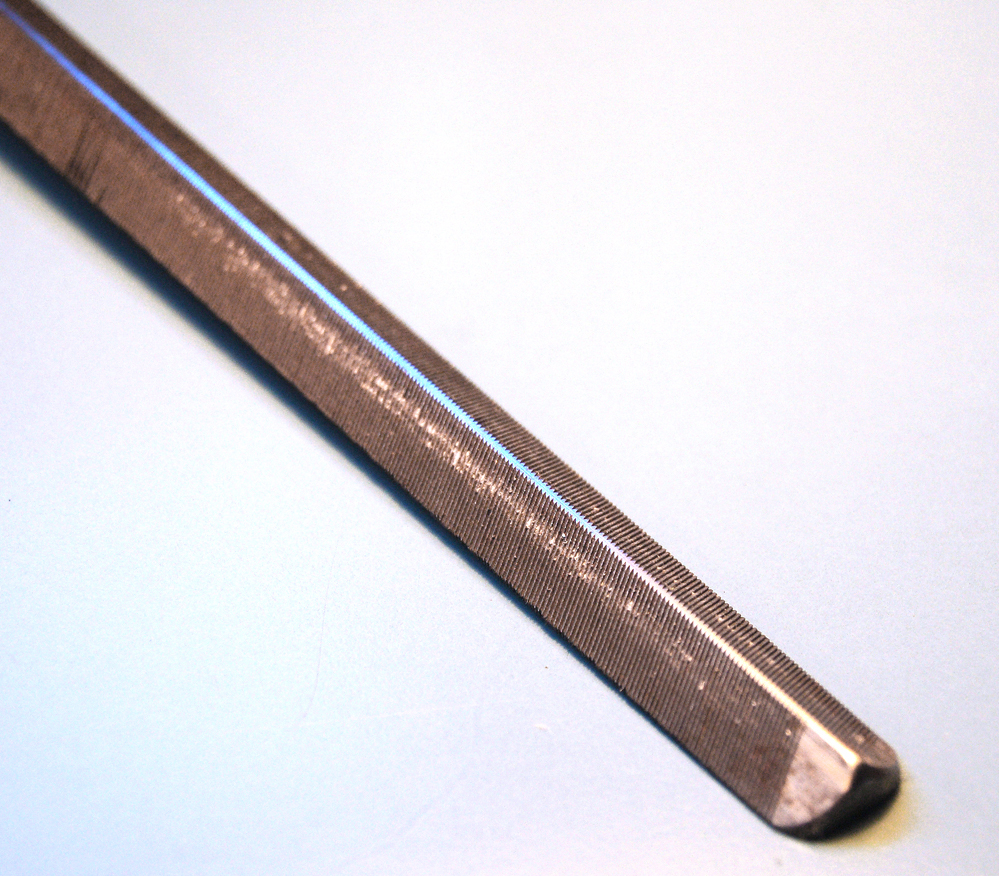

slot there is with one of these tools. As in many other realms of lutherie, it's not the tool that does the work, but the person using the tool. I've seen plenty of really bad nuts and saddles done by inexpert hands using the finest tools money can buy. I have drawers full of all kinds of files, but let me start with the essentials: The 3-square jeweler's needle file is triangular in section; it's not square. I love the term "3-square," even though it makes no sense.  I use two:  The larger is about 6" OAL, with a working surface of about 3". It's a #0 cut, which is fairly coarse within the range of needle files—#00 is coarsest, and the finest is supposedly #8. I don't believe I have ever seen, much less used, a needle file finer than a #4, which is good for very refined work on gold and platinum. Bone, ivory and so on, usually need an "0" cut. I use this to start larger slots accurately, and even do slots for very heavy plain strings and very light wound strings. The #0 cut really cuts quickly, and that cut is too coarse for most plain strings on instruments. It makes a good firm first cut, but with the exception of, say, an .022" guitar G string, you would want to refine the cut later with a more appropriate file. I also use a finer one (the one with the round ball handle) that's about 5-1/2" with a 2-1/2" cut length, or working surface, in a #2 cut. This will do .008" string slots and with a little rocking, up to maybe .018" Round tapered "jeweler's" files are next. Again, the useful size for the luthier's shop are a larger one (for strings from low A's on guitar to cellos) and a smaller one, which will take you from the typical guitar A down to about .020"w strings.  The best of these by far is a Grobet item that Shar in Ann Arbor once marketed as a "mousetail" file. It has a square shank, is about 7" long with a 3" working surface, and comes to an incredibly fine (and fragile!) tip:  This is actually an escapement file, not a jeweler's file. It's made for cutting steel in watch and clock gears, so it's tougher and lasts longer than typical jeweler's files. The square shank tells you its an escapement file. They run about $20 apiece. I can't find this file in Grobet's own catalog, though mine have Grobet stamped right on them. A few other vendors sell them; Google "escapement file" but know that many of the ones you see are just round tapered jeweler's needle files. Check the shape of the shank: you want a square one. Claro? Another shot:  The tips of these do a sweet job of an .020" slot. Note the square shank. Here's a final slot cutting tool that many folks have not encountered: a diamond-coated tapered round file. I get mine from Rio Grande. It's meant for opening the holes in pearls.  It's extremely fine—you could conceivably dress a slot of an .013" string with it—but its diamond coated surface clogs a bit too easily on most materials, except...pearl! And it's flexible. If you bend it, you can straighten it. Hallelujah. (I do slots in pearl nuts with this—and water.) The cant saw file was originally intended for sharpening "M" type hand saws. The good size is 6".  They are a little hard to find, but worth the search. Nicholson still makes them, but the best is finding new-old stock in Nicholson or Symonds. They are incredibly useful in two ways: 1) the two simple acute edges are great for starting or roughing in large slots: cello strings, fatter guitar strings and so on. 2) with the ends blunted and polished, and with the oblique-angle spine ground and polished safe, they are terrific for crowning frets and dressing the ends.  Making the edge and the end safe is essential. Here's the before and after:  Doing the end is critical if you're working on fret ends on a fingerboard that's flat on a top. Of course you'd have that area masked anyway, but rounding those leading edges makes the end of the file skid, rather than dig in and possibly penetrate, the masking tape if you have an 'oops." Prepared cantsaw files have a third major use, which is to chamfer the front edge of the nut prior final polishing. For this, I lay a piece of tape across the board just in front of the nut, and relieve that edge in a couple of passes. Cantsaw files are a bit clunky for dressing finer frets, so for that I again resort to the jeweler's file world, and a needle file called a slitting file:  Again, it's tiny: 6" overall length, 2-3" of cutting surface, and like the cant saw file, it needs to be dressed for the job. But the acute-angle edges are still good for their original intention: cutting (slitting) fine slots. Here's the one I have used exclusive since 1965:  Most of the files on the market now have a lozenge shape that's too flattened; my veteran here (made by the Swiss outfit called Baiter, very hard to find) is just right. Miraculously it's still working after more than 45 years. I save it for dressing really tiny frets.  The handle here is a piece of brass tubing, as the original tang snapped decades ago.  I have tried to adapt square

files with safe edges to do the work of these flattened

files and they don't quite do the job. The typical files

sold by the luthier suppliers (right) similarly make big

messes. I have tried to adapt square

files with safe edges to do the work of these flattened

files and they don't quite do the job. The typical files

sold by the luthier suppliers (right) similarly make big

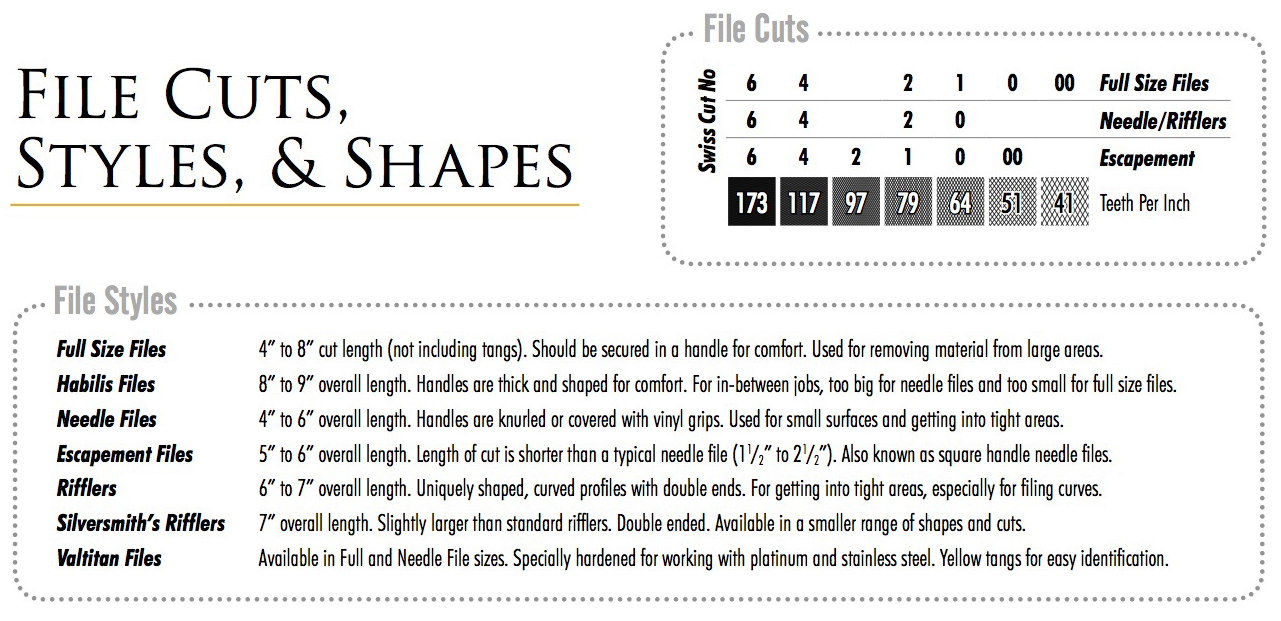

messes. I have found that I can dress a cantsaw file with a slightly broader safe edge and it can chamfer and dress the lengths of frets as well as chamfer the ends quite well. Part of this is the tool, the more important part is the technique. Here's a decent chart about files:

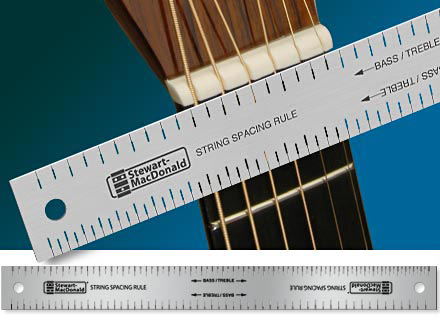

Where to get various files like these: Dictum (merger of Herdim with Dick) Otto Frei Rio Grande (they also sell the best jeweler's saw blades on the planet) Artco Stewart-MacDonald Grobet I get my escapement files from a dealer on eBay called "FavoriteUSA," a jeweler's supply outfit in NYC. Last I checked, this link worked: http://www.ebay.com/itm/281359250198?_trksid=p2059210.m2749.l2649&var=580390912442 If you have any other great sources, I'd love to hear about them. A couple of nifty tools every luthier needs: A good fine set of dividers—really precise ones like these Starretts:  Accept no substitutes. The most infinitesimal twist of the wheel results in the solidest and most meaningful mark from point to point. Don't go near a mandolin or a violin without one of these. Another is Stew-Mac's graduated string spacing rule. This is a tool for the terminally anal setup specialist, but I kind of dig it just because it exists:  Odd that they displayed it with such a miserably cut nut, but it's a tool you can certainly do better with. They are terrific with 12-string guitars, mandolins, and the like as well. Speaking of which, check my page on cutting nuts right here. Or, go back to the repair index page.

|

|||||||||||||||||||||||||||||||||