| Paul Hostetter, luthier bowed instruments plectrum and other instruments professional background art plastic!

Email:

click

here Manouche-Tone

Strings

|

New

dimensions

in travel guitars…

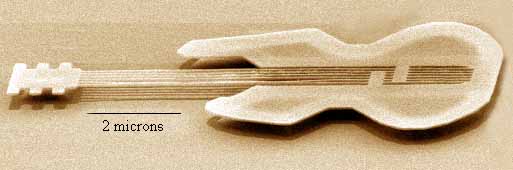

In the summer of 1997, at the Cornell Nanofabrication Facility in Ithaca, New York, doctoral student Dustin Carr built a "nanoguitar." At a mere 10 microns long from strap button to headstock, it’s one of the world’s smallest silicon mechanical devices. By comparison, the diameter of a human hair is 200 microns. (A micron is one-millionth of a meter; a nanometer is one-billionth of a meter.)

Each of the guitar’s six strings measures about 50 nanometers—a mere 100 atoms—wide. An atomic force microscope plucks the strings, producing a sound that (as you might imagine) is inaudible to the human ear. Carr used a high-voltage electron-beam machine to craft the solidbody guitar out of a single crystal of silicon. The project is also a significant milestone in the quest for building smaller computer chips studded with even more transistors than today’s. Most "microelectromechanical" devices, including your computer’s microprocessor, are made by photolithography and chemical etching. But these processes can’t produce "features" much smaller than 1 micron. (The Pentium II uses a 0.35-micron process.) Building devices of nanometer dimensions requires a more precise technique known as electron-beam (E-beam) lithography, which involves scanning a beam of electrons across a surface covered with a sensitive film (called a "resist"). The electrons produce a chemical change in the film that produces a pattern—in this case, a guitar. You have to admit, this is a strange new realm of lutherie. Just consider the rapid march of technology in the chip-making business: Intel’s 386 microprocessor had 275,000 transistors; the 486 had 1.2 million; the original Pentium has 3.3 million; and the Pentium II has a whopping 7.5 million. To top it off, chip sizes shrink with each generation. Want to see the new model, and some updates? Click

here.

Drop

me

a

line

click

here | |